As it was already mentioned – in every case, proper ground floors preparation prior to the installation of actual floor is the key for achieving best possible parameters and aesthetic appearance. Especially, with regard to the fact, that renovation of old and damaged surfaces is a very common case.

Application of traditional repair technology, removal of old concrete, rubble disposal and installation of new concrete ground floor is an extremely long and expensive (although effective) method.

Application of popular self-levelling mixes is not very effective, due to the fact that hardness and mechanical parameters of these levelling mixes are different than the surface mixes parameters. Consequently, these levelling mixes crack under high mechanical load, causing damages to actual floor coatings.

We have worked out several types of regenerating plastics for immediate ground floor repairs. These plastics are used only for filling holes, cavities and levelling the actual surface. They are manufactured from the same epoxide resin „family” and are fully compatible with all other PLASTIPOX plastics, which greatly decreases the risk of floor ply separation during its exploitation.

For basic data on regenerating plastics, see the table below:

| PLASTIC’S SYMBOL | SPECIFIC GRAVITY [g/ccm] | VISCOSITY (A+B) | SPREADABILITY {A+B) | ADHESION TO CONCRETE | WATER RECEPTIVENESS |

| PLASTIPOX 5FI-r | 1.7 – 1.9 | 17.5 – 22.5 | min. 20 | Min. 35 | < 1.0% |

| PLASTIPOX DZE-r | 1.9 – 2.1 | „wet sand” | – | Min. 26 | < 1.0% |

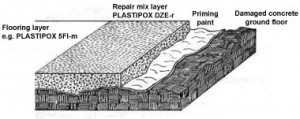

A typical scheme of damaged concrete ground floor repair work is shown in the draft below. A concrete layer painted with priming plastic is covered and levelled with repair mix (e.g. DZE-r) and smoothed with trowel for even surface. Finally it is covered with chosen type of actual floor (e.g. 5FI-m).